2023 has heralded an interesting time in the CPG industry. According to recent NIQ research, the CPG industry has experienced double digit growth over the past year, but inflation and consumer trends towards buying in bulk, moving to private label, and buying on promotion make it a challenging market to read. Never has a clear understanding of what’s happening at “the moment of truth” when a shopper (or a third-party picker) is standing in an aisle, looking at the shelf and ready to buy (or fulfill) been more important.

At Pensa Systems, we’re hearing about these market dynamics every day from our customers. More and more, dealing with these pressures leads to a discussion with our customers about how best to plan the shelf and how to ensure better in-store execution of those plans. Planning to optimize the shelf and taking the subsequent actions to turn optimization planning into reality are two aspects of improving shelf performance that were featured on a recent webinar sponsored by our partner Acosta. Mark Abernathy, Pensa’s Head of Retail, and Dave Schoewe, Acosta’s Vice President of Transformation, had an engaging discussion on shelf optimization. You can check out highlights here.

An important segment of the discussion highlighted the relationship between accurate shelf-inventory data and shelf optimization plans that drive results. The adage of “garbage in, garbage out” is applicable to the idea that an optimized shelf is an appropriately stocked shelf as an inaccurate understanding of shelf inventory conditions will lead to less than optimal in-stock levels.

It likely goes without saying that product availability is a top driver of CPG sales. Whether it’s measured as in-stock levels, out-of-stock levels, or on shelf availability, if the product is not available for sale or fulfillment on the shelf, sales will suffer. One of the key webinar discussion points was the common misperception by CPG brands about just how successful they are at keeping their products available to purchase or fulfill on retail shelves.

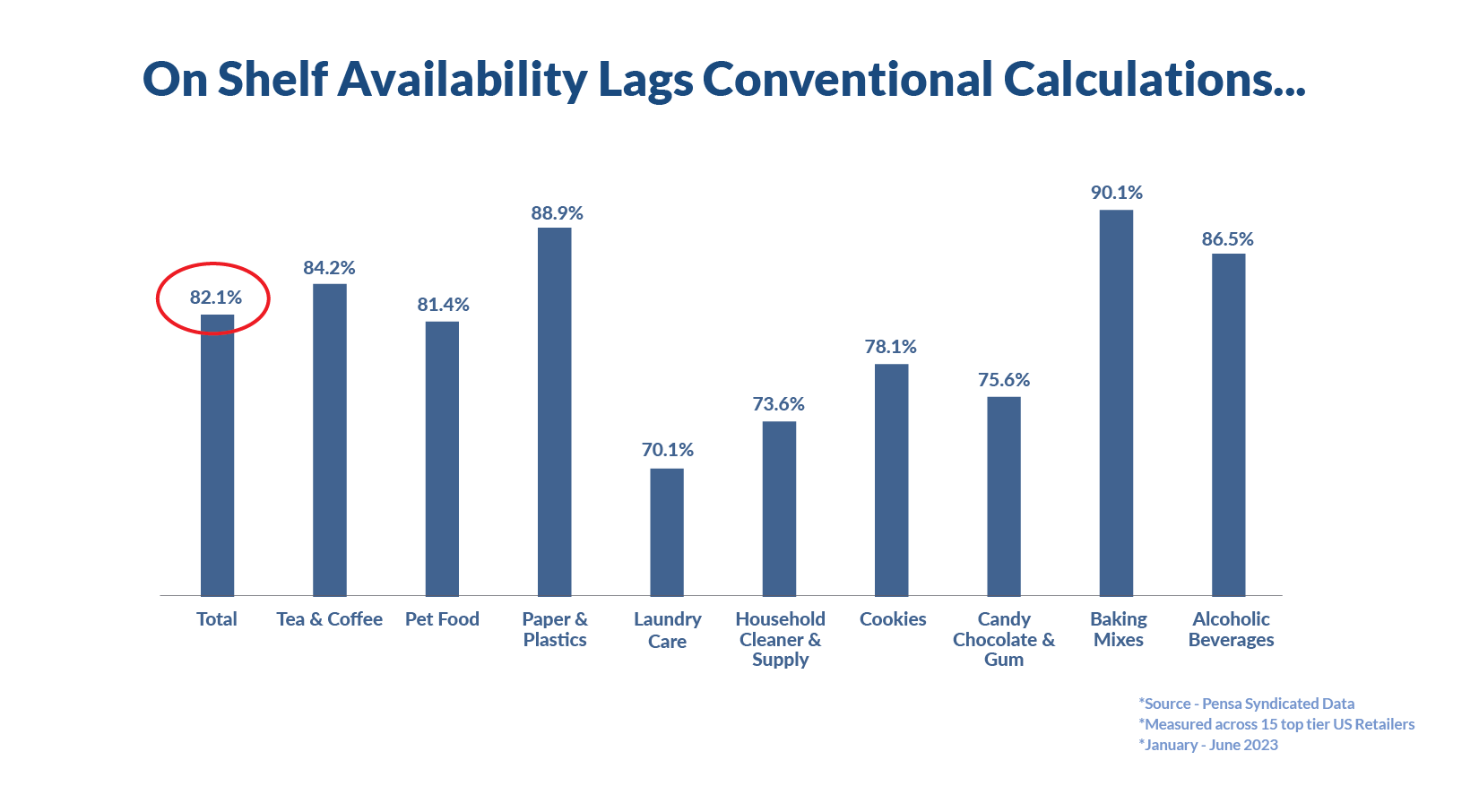

Historically, it’s been broadly assumed in the CPG industry across many categories that product on-shelf availability is typically a non-issue in terms of its impact on growth. It’s a common assumption that on-shelf product availability is typically 90-95% or higher. This assumption is likely founded in traditional approaches to measuring product availability based upon to broad brush point of sale data sometimes combined with perpetual inventory levels. The reality is that actual on-shelf availability, measured through a precise understanding of product on-shelf inventory conditions, significantly lags this conventional belief. This table reflects measurement of product availability for the first half of 2023, overall and for several key categories.

The “assumed data” from traditional approaches to shelf inventory management is not necessarily reality. In many cases, advances in technology that have resulted in new data sets highlight a stark difference between shelf assumptions and shelf reality. That reality is reflected in the table above.

On the webinar, Dave brought up the “old retail saying” that “retail is detail”. Given the current market pressures, never has a detailed understanding of what SKUs are on the shelf and available for sale at any given moment been more important. To that end, Mark provided a comprehensive overview of the latest in shelf intelligence solutions with an emphasis on comparing different computer vision and artificial intelligence approaches that represent the latest innovation in delivering accurate and detailed shelf inventory data. You can watch the webinar replay here.

If you are interested in learning more about how Pensa and Acosta can help you grow your business through a better understanding of shelf inventory and how you can take appropriate in-store action based upon that understanding, please contact us and we’ll get something scheduled.