A Painful Marketplace Reality

Nobody likes their products out of stock on the retail shelf. Not the consumer, not the retailer, not the manufacturer.

There are lots of reasons why the shelves these days are missing items. Certainly, supply chain problems are endemic to the world today in times of COVID. And many real-world considerations exist to create demand for products that result in out of stocks including local events, new product launches, promotions, weather and notably, shopper shifts to more omnichannel commerce.

This is shared pain for all players in the industry to solve, working together end-to-end to do so.

Current Demand Forecasting is Broken

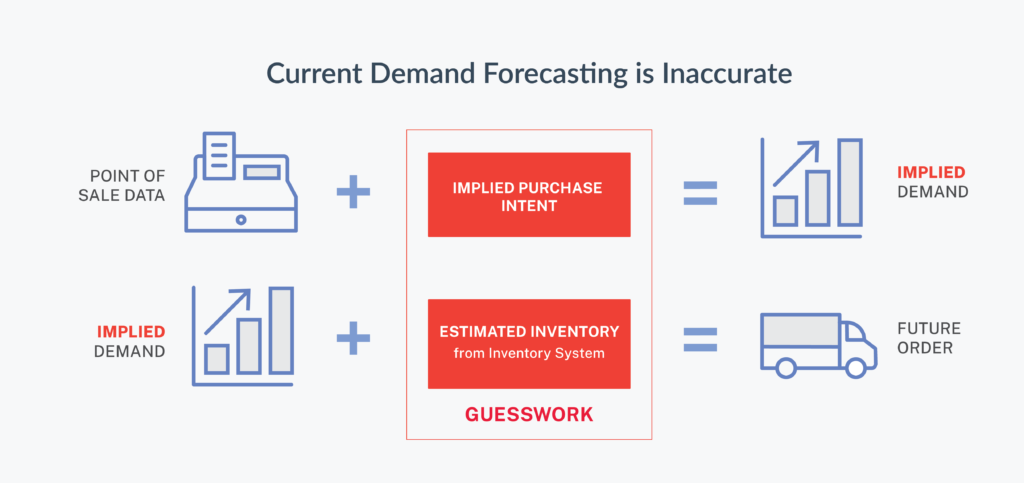

Yet, the industry has been working with one hand tied behind their back. While systems are very advanced for tracking and managing the logistics of supply chain, deliveries and warehousing, there is no system of record and no shared truth for what is actually happening after products arrive at the store loading dock. Products enter a black hole leaving manufacturers, retailers and many times, the consumers to guess about the true state of in-store and on shelf inventory. And consequently, leaving brands and retailers to base demand forecasting on belief instead of data-driven reality.

Point-of-Sale Provides Noisy and Inaccurate Data

Demand drives consumption, and consumption begins with purchase. And purchase requires the products to be on the shelf to grab. Yet, the industry doesn’t actually know what is on the shelf and available to buy. Point-of-sale (POS) data, that is, cashier scans at checkout, is available and often used to predict “demand”. Yet, it isn’t demand in a forward sense, it only says what has sold historically in the past. And accuracy of POS data is limited because POS data is noisy – it can be impacted by numerous factors including shrink (lost product due to theft), waste (lost product due to disposal or price reduction), or cashier error or shortcuts.

Inventory Systems Are Not Sufficient

What else contributes to significant inaccuracies in forecasting demand? Ironically, the retailer inventory systems themselves. While meant to provide an accurate view of in-store inventory, these systems are notoriously inaccurate and reflect stock that’s supposed to be present. Typically, these inventory systems measure stock as it arrives at the loading dock of the store, but quickly lose visibility of when and where products are placed in the store, or if products even make it out onto the store floor at all. This is exacerbated by stock placed by direct store deliveries (DSD) from the suppliers, which in most cases don’t leverage retailer inventory systems. Retailers simply don’t know if DSD items are actually on-hand in the store at all. When combined with POS data, you get the worst of all worlds – that is, what could be a signal of no demand since the products aren’t being grabbed from the shelf, when in fact they aren’t there on the shelf in the first place.

This poor visibility creates product-level demand forecasting errors that compound to produce significance distortion in overall demand forecasting. Leading to too much of the wrong product being produced or not enough of the right product being produced which ultimately leads to increased waste and reduced profitability.

A New Data Signal to Dramatically Improve Demand Forecasting

Shelf data is the absolute truth and the missing ingredient to predict future sales more accurately.

An accurate and comprehensive view of product on-shelf availability measures whether the product is really available on the shelf to buy…and how that purchase (or not) is influenced by whether competitive products themselves are on the shelf. Also understanding where in the store products are available is important – you know, in the end cap where you didn’t look versus in the normal place on the shelf where you did. This lack of on-shelf product availability data is currently resulting in grossly inaccurate demand forecasting.

Pensa has been working with major retailers, packaged goods manufacturers, and delivery partners to increase the accuracy of demand forecasting by incorporating a smarter signal to better predict future purchase. Highly accurate, real-time on-shelf product availability data is an indicator of consumer intent to purchase that can be used to better predict future demand.

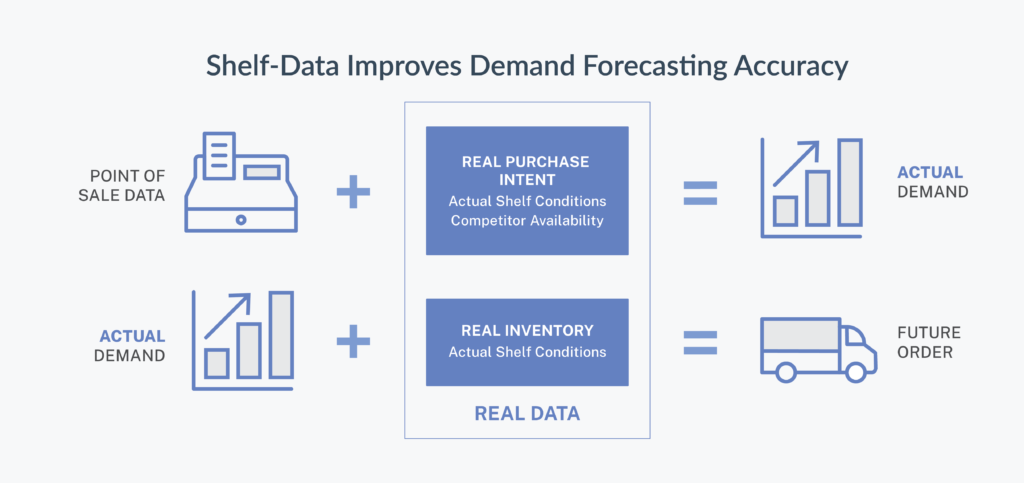

Point-of-Sale and perpetual inventory data alone can never be a reflection of true demand; leading manufacturers, retailers and delivery partners are leveraging innovative new data signals such as on-shelf-availability to create a much more accurate measure of intended purchase.

Are you seeking to improve profitability through more accurate demand forecasting? Let’s talk. Pensa may be able to help.